This section provides guidance on Non-Stormwater and Waste/Material Management, Section 5 in the Construction BMP Handbook.

A PDF of this entire section can be downloaded here.

Click on the topics below to navigate to each section.

DESCRIPTION

This BMP reduces the amount of water consumed for a given activity, thereby reducing the chance of erosion and transport of pollutants off-site.

GUIDELINES

- Avoid overfilling watering equipment. If overfilling persists, stabilize the area and provide means to control the runoff.

- Discourage on-site vehicle and equipment washing.

- Avoid cleaning construction areas with water. If water must be used, first sweep and vacuum to minimize amount of water needed.

- Always protect storm drain inlets or natural waterways from sediment and pollutants generated by watering activities.

- Direct non-polluted runoff into areas on-site where it can percolate into the ground or be collected and reused.

- Water equipment should be kept in good working order.

- Always promptly repair leaky watering equipment.

- Lock water tank valves to prevent unauthorized use.

MAINTENANCE AND INSPECTION

Inspect water equipment at least weekly, and repair as needed:

- Water trucks

- Water reservoirs

- Irrigation systems

- Hydrant connections

Inspect all non-stormwater management BMPs daily when discharge occurs.

DESCRIPTION

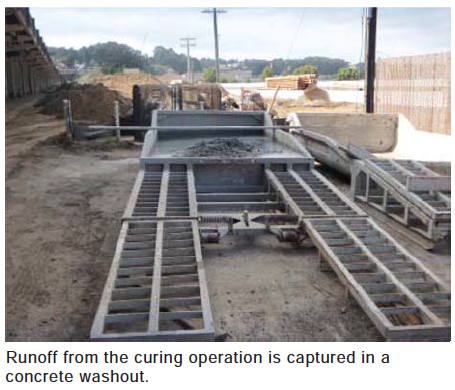

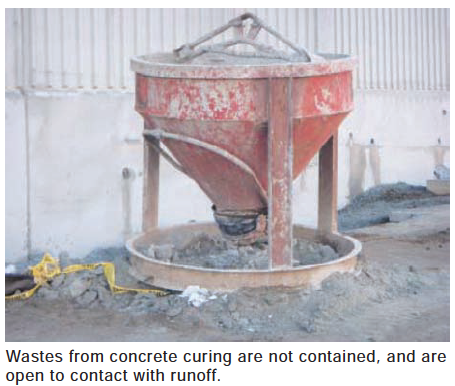

Concrete management includes the proper procedures to reduce or eliminate the contamination of stormwater runoff during concrete curing, cutting, drilling, and coring. Discharges of stormwater and non-stormwater exposed to these concrete activities may have a high pH and may contain chemicals, metals, and fines. Proper procedures reduce or eliminate the contamination of stormwater runoff during these procedures.

GUIDELINES

This BMP is suitable for all projects where Portland Cement Concrete (PCC) and concrete curing chemicals are placed where they can be exposed to rainfall, runoff from other areas, or where runoff from the PCC will leave the site. Concrete management is also applicable on projects where asphalt is used or where slurry or pavement/ concrete wastes are generated by construction activities, including: saw-cutting, coring/drilling, grinding, repaving or patching, and encasing conduit in concrete.

All operations shall adequately mitigate polluted water discharge, capturing all runoff from curing.

MAINTENANCE AND INSPECTION

- Inspect containment structures prior to rainfall and prior to and during use.

- Required repairs must be done before a rain event and in a timely manner.

- At the end of a shift or after use, ensure containment structures and the general work area are clean. Properly dispose of all wastes.

DO

DON'T

DESCRIPTION

This section discusses the handling of materials and wastes for (and the use of equipment associated with) pavement preparation, paving, surfacing, resurfacing, paint striping, thermoplastic striping and placement, and the removal of all the above.

This section discusses the handling of materials and wastes for (and the use of equipment associated with) pavement preparation, paving, surfacing, resurfacing, paint striping, thermoplastic striping and placement, and the removal of all the above.

GUIDELINES

- Install BMPs prior to beginning paving and grinding operations.

- Avoid paving during wet season.

- Collect and remove grindings and wastes from removal of pavement and related materials as the work progresses.

- Temporary waste stock piles containing wastes from paving and grinding need to be covered with plastic sheeting until removed from the site.

- Asphalt concrete placement and removal equipment needs to be cleaned off-site.

- Do not apply seal coat, tack coat, slurry seal or fog seal during rain or if rain is expected during curing period. If unexpected rain occurs, capture all runoff from treated areas, and dispose off-site.

- Prior to operation, verify that shut-off valves are operable on painting and thermoplastic applying equipment. Do not overfill the thermoplastic pre-heater to prevent spills. Clean truck beds daily and recycle thermoplastic material when possible.

MAINTENANCE AND INSPECTION

Inspect and maintain machinery regularly to minimize potential leaks.

DESCRIPTION

This BMP provides the proper procedures for delivery and storage of the following:

- Soil stabilizers and binders

- Detergents

- Plaster

- Petroleum products such as fuel, oil and grease

- Asphalt and concrete components

- Hazardous compounds such as acids, lime, glues, adhesives, paints, solvents, and curing compounds

GUIDELINES

Examples of Improper Storage

DESCRIPTION

This BMP describes proper procedures for stockpiling construction material. Stockpile protection is a year-round requirement.

MAINTENANCE AND INSPECTION

Stockpiles should be checked weekly, prior to rain events, daily during extended rain events, and after rain events. Remove sediment from stockpile perimeter controls when sediment reaches 1/3 of the barrier height.

DO

DON'T

DESCRIPTION

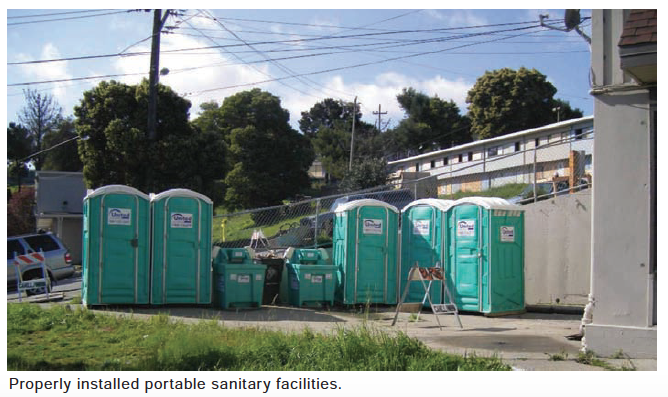

Measures must be taken to keep waste from portable sanitary facilities out of the storm drain system, natural waterways, and channels. Discharges to city sanitary sewer systems are not allowed from sanitary facilities.

GUIDELINES

- Locate temporary sanitary facilities behind sidewalks and away from storm drain inlets, natural waterways, channels and traffic areas.

- Anchor the sanitary facility to the ground as a precaution for both vandalism and high winds.

- Do not discharge, dump, or bury wastewater on private or public property.

- If a spill occurs from the facilities, follow federal, state, and local regulations for containment and clean-up.

MAINTENANCE AND INSPECTION

The general contractor monitors any sanitary/septic waste storage and disposal procedures on a weekly basis. The contractor is responsible for ensuring that the sanitary/septic facilities are maintained in good working order and wastes are transported offsite by a licensed sanitary service provider.

DO

DON'T

DESCRIPTION

This section describes proper hazardous waste handling procedures to prevent associated pollutants from entering stormwater.

Hazardous waste includes but is not limited to the following substances: petroleum products, concrete curing compounds, sanitary wastes, paints, stains, wood preservatives, asphalt products, pesticides, acids, solvents, and roofing tar. If non-hazardous waste comes into contact with the above wastes, it is considered hazardous.

Sites with existing structures may contain wastes which must be disposed of in accordance with federal, state, and local regulations, including: sandblasting grit mixed with lead, cadmium, or chromium-based paints; asbestos; and polychlorinated biphenyls (PCBs).

GUIDELINES

- Refer to the applicable Material Safety Data Sheet (MSDS) for clean-up and reporting procedures for all hazardous spills.

- Do not remove the original product label; it contains important safety and disposal information.

- Use secondary containment berms in fueling areas.

- Place hazardous waste collection containers at convenient locations.

- All hazardous waste must be stored within secondary containment.

- See Hazardous Materials BMP Section for additional guidelines.

- Containers properly labeled: name, address, and US Environmental Protection Agency (EPA) identification (ID) number or ID number of generator listed (not required if contractor is an exempt small quantity generator).

- Do not store different wastes in the same container. Do not store incompatible materials in the same temporary containment facility.

- Hazardous waste shall be transported from the site by a licensed hazardous waste transporter and disposed of at an authorized, licensed disposal or recycling facility within 90 days of being accumulated.

- Properly dispose of rain water removed from temporary containment areas that may have mixed with hazardous waste.

- Educate contractor and subcontractors regarding identification, storage, and disposal of hazardous waste. Ongoing hazardous waste training should be included in regular safety meetings.

examples of improperly contained concrete mixtures

DESCRIPTION

Materials that are collected and disposed of on-site in solid waste storage bins cannot come in contact with stormwater runoff.

Solid wastes include items such as:

- Construction wastes including brick, mortar, timber, steel and metal scraps, pipe and electrical cuttings, non-hazardous equipment parts, Styrofoam, and other materials used to transport and package construction materials.

- Scrap or surplus building materials including metals, rubber, plastic, glass pieces and masonry products.

- Domestic wastes including food containers such as beverage cans, coffee cups, paper bags, plastic wrappers, and cigarettes.

- Planting wastes including vegetative material, plant containers, and packaging materials.

GUIDELINES

- Solid waste should be stored at a location which is least likely to be flooded and at a location away from a storm drain, natural waterway, or drainage channel.

- Use berms, dikes, or other temporary diversion structures to protect stockpiled waste from contacting stormwater.

- During rain events, waste materials need to be stored in watertight dumpsters and kept securely covered. Liquids must be kept out of dumpsters and waste receptacles. The areas around the dumpsters should be swept daily.

- Provide an adequate number of trash receptacles on-site including field trailer areas and where workers gather for breaks except near drainage inlets, natural waterways, or drainage channels. All litter within the construction site should be collected weekly, regardless of the litter’s origin. Litter needs to be removed from the site by a licensed solid waste contractor.

- Provide an adequate amount of watertight dumpsters to collect the anticipated volume of construction waste. Also, plan for additional dumpsters to be delivered to the site and schedule additional pickups during demolition phases. Washing out dumpsters on the construction site is prohibited.

MAINTENANCE AND INSPECTION

Construction debris and waste should be removed from the site biweekly or more frequently as needed. Arrange for regular waste collection.

DESCRIPTION

This section describes proper procedures to prevent non-hazardous liquid wastes from entering the storm drain system. This section does not apply to the following: dewatering operations, solid wastes, hazardous wastes, concrete slurries, and liquid wastes covered by specific laws or permits.

This BMP addresses non-hazardous liquid wastes:

- Drilling slurries and fluids

- Dredgings

- Other non-storm water liquid discharges, which are not covered by separate permits

- Grease and oil-free wastewater and rinse water

GUIDELINES

- Use temporary dikes or berms to direct surface flow of liquid wastes to a containment structure or device. The containment area should be structurally sound, leak free, and have sufficient storage for anticipated volume.

- Appropriate structures include holding pits, sediment basins, roll off bins and portable tanks. Locate the containment structure far from storm drains, natural waterways and drainage channels.

- Some liquid wastes may require testing and certification that they are non-hazardous before an appropriate disposal method is selected.

- Educate employees and subcontractors on liquid waste generating activities and liquid waste storage and disposal procedures.

- Refer to Vehicle and Equipment Cleaning BMP when applicable.

- Avoid spills or accidental releases of contained liquid wastes. Apply Spill Prevention and Control BMPs as needed.

MAINTENANCE AND INSPECTION

- Remove deposited solids in containment areas and capturing devices as needed, and at the completion of the task. Dispose of any solids as described in Solid Waste BMP.

- Inspect containment areas and capturing devices and repair as needed.

- Frequently inspect liquid waste containment areas and capturing devices for damage, and repair as needed.

examples of improperly contained liquid waste

DESCRIPTION

Spill prevention and prompt appropriate spill response reduces the potential for discharging pollutants to drainage system. Typical spills of concern include chemicals and hazardous waste such as soil stabilizers/binders, dust palliatives, herbicides, growth inhibitors, fertilizers, petroleum, products, fuels, pesticides, lubricants, paints, and solvents.

GUIDELINES

In preparation of a potential spill, locate and clearly label spill-kits and disposal containers. Appropriateness of the response is determined by the quantity and/or composition of the spilled substance as follows:

MAINTENANCE AND INSPECTION

- Keep ample supplies of spill control and cleanup materials on-site, near storage, unloading, and maintenance areas.

- Update the spill prevention and control plan, and stock cleanup materials as changes occur in the types of chemicals on-site.

examples of improperly contained liquid waste

DESCRIPTION

DESCRIPTION

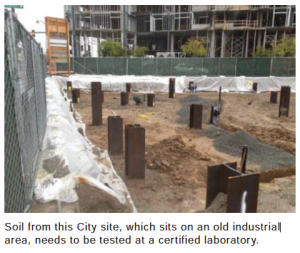

This section is particularly applicable when conducting construction in highly urbanized or industrial areas where soil contamination may have occurred due to spills, illicit discharges, and leaks from underground storage tanks.

GUIDELINES

The procedures and practices presented in this BMP are general. The contractor should identify appropriate practices and procedures for the specific contaminants known to exist or discovered on-site. It is important to confirm a site assessment before moving soil.

Identify contaminated soils by investigating the following items:

- Past site uses and activities.

- Detected or undetected spills and leaks.

- Acid or alkaline solutions from exposed soil or rock formations high in acid or alkaline forming elements.

- Contaminated soil as evidenced by discoloration, odors, differences in soil properties, abandoned underground tanks or pipes, or buried debris.

- Contaminated soil is prohibited from entering storm drains, natural waterways, or drainage channels.

- Depending on the type of contamination, different handling requirements will need to be met. In some cases, contaminated soils may need to be placed in steel barrels, sealed, and removed from the site. This waste will need to be taken to a licensed hazardous waste disposal site. Along with this, soil testing for contaminants in stormwater may be required at the discretion of the Construction or Stormwater Inspector.

- Avoid stockpiling contaminated soils. If stockpiling is necessary and allowed, cover the stockpile and install a berm around the pile to prevent runoff for secondary containment.

All suspected soils should be tested at a certified laboratory.

DESCRIPTION

This section describes how to properly store and dispose of paint, stucco, and associated tools.

This section describes how to properly store and dispose of paint, stucco, and associated tools.

GUIDELINES

Contact your local jurisdiction to locate facilities that accept paint cans, paint, solvents, and thinners.

- All paint and stucco materials stored on-site must be contained and covered.

- It is illegal for contractors to wash out paintbrushes in the street or dump any residues in the sewer/storm drain.

- Paintbrushes, spray guns, and other tools must be washed/cleaned out into a hazardous materials barrel or original container. Avoid doing this where wash water can flow to the storm drain, even if the paint is latex.

- Paint out brushes as much as possible. Always wash brushes with latex paint in a sink that goes to the sanitary sewer.

- Clean up latex paint spills with rags and wash in the sink. Avoid using oil-based paints, which require solvents. Filter and reuse thinners and solvents.

DESCRIPTION

This section describes how to recognize and report illicit connections or illegally discharged material on a construction site. Illicit discharges are generally any discharge into a storm drain system that are not composed entirely of stormwater.

GUIDELINES

Before beginning the job, inspect the site for evidence of illicit connections, illegal dumping, or discharges. Observe site perimeter for evidence for potential of illicitly discharged or illegally dumped material that may enter the job site.

Inspect the site regularly to check for any illegal dumping or discharge. Prohibit employees and subcontractors from disposing of non-job related debris or materials at the construction site.

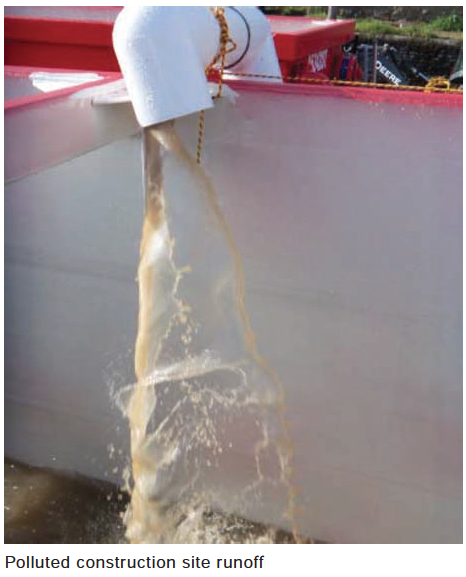

examples of illicit discharge and waste

DESCRIPTION

Dewatering operations include the proper procedures for managing the discharge of stormwater and non-stormwater from the construction site.

GUIDELINES

- Sediment treatment options include: sediment traps, dewatering tanks, weir tanks, cartridge filters, and pressurized bag filters. See the Caltrans Dewatering Operations guidelines for further information regarding the tanks and filters.

- The contractor is to provide a dewatering plan that details the location of dewatering activities, equipment, and discharge point.

- Retain water on the site for construction use. Re-use water for dust control, irrigation or another on-site purpose to the greatest extent possible.

- Discharging construction site waste to the sanitary sewer is a final option and requires a Batch Wastewater Permit.

- Appropriate wastewater treatment or off-site disposal will be required in those situations where the initial sampling and analysis reveal noncompliance with the applicable regulatory limits.

- When flushing chlorinated water lines, test and remove all chlorine content before discharging to the sewer system.

- Dewatering discharges must not cause erosion at the discharge point.

MAINTENANCE AND INSPECTION

Inspect all BMPs frequently, and repair or replace to ensure the BMPs function as designed. Accumulated sediment removed during maintenance of a dewatering device must be disposed of according to the Registered Engineer. If the sediment contains hazardous pollutants, it must be removed in accordance with the guidelines for Hazardous Waste.

DO

DON'T

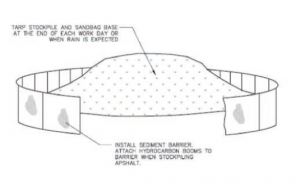

Install temporary barriers around the stockpile perimeter to prevent contact with runoff. Temporary barriers may be berms, dikes, silt fences, fiber rolls, and gravel bag berms. Attach hydrocarbon booms to barrier if stockpiling asphalt; the booms absorb the oil and prevent it from leaving the site.

Install temporary barriers around the stockpile perimeter to prevent contact with runoff. Temporary barriers may be berms, dikes, silt fences, fiber rolls, and gravel bag berms. Attach hydrocarbon booms to barrier if stockpiling asphalt; the booms absorb the oil and prevent it from leaving the site.